Key Takeaways:

Key Takeaways:

- CPVC pipes can cause plumbing issues in Houston homes.

- CPVC can become brittle over time, making it prone to cracking and breaking

- The glue that holds CPVC pipes together can deteriorate, causing pipes to shift

- PEX and copper prove to be stronger and more long-lasting materials for home plumbing.

Most people never give their home plumbing a second thought until something goes wrong. Knowing what type of pipe has been installed in your walls can often help you prevent developing problems before they result in costly repair bills.

Chlorinated polyvinyl chloride (CPVC) pipes are proving problematic for homeowners in Texas and across the nation because of their limited longevity and tendency to become brittle and crack over time. This can cause leaks inside walls that may go undetected until serious damage has occurred. Consulting with a reliable Houston plumber can help you identify and mitigate these risks before they become full-scale repair issues.

The History of CPVC Pipes for Houston Plumbing

Using CPVC pipes for home plumbing dates back to the mid-20th century as a solution to the limitations of existing materials like metal and standard PVC. While PVC was in use, it lacked the temperature and pressure resistance needed for hot water applications.

In the late 1950s, B.F. Goodrich pioneered a process to chlorinate PVC, which created a more thermally stable material capable of withstanding the heat and pressure of residential hot and cold water distribution. The first CPVC plumbing system was installed in a research home in Michigan in 1959 as part of a program by the National Association of Home Builders.

The success of these early trials led to the material’s commercial production in the 1960s. By the 1970s and 1980s, CPVC gained widespread code approval and popularity across the United States, providing a durable, corrosion-resistant, and cost-effective alternative to traditional copper and galvanized iron pipes.

Issues with CPVC Pipes

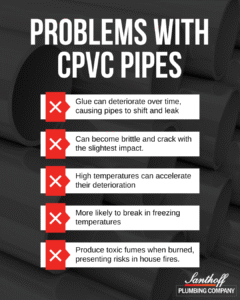

CPVC pipes were designed to provide an inexpensive alternative to other materials and to reduce the effects of acidic water on pipe longevity. Despite its advantages, CPVC piping has several notable downsides that homeowners and plumbers must consider.

A primary concern is its susceptibility to brittleness over time, especially when exposed to UV light or certain chemicals found in everyday household products, which can lead to cracking and failure. This can be a major problem if pipes are installed in areas where they are exposed to sunlight or chemical fumes, such as in an uninsulated garage. Furthermore, the material can become more rigid with age, making it prone to shattering from physical impact or stress.

CPVC is also vulnerable to degradation from chlorine in municipal water supplies, which can weaken the pipe walls from the inside out and reduce its overall lifespan. Lastly, the installation process, which relies on solvent cement, can be a point of failure if not performed perfectly, as improper application can lead to weak joints and leaks.

Another problem with CPVC pipes is the glue used to hold them together. When applied, the solvent cement temporarily dissolves the top layer of the CPVC pipe and fitting. This “melts” the two pieces together, and as the solvent evaporates, the materials fuse into a single, homogenous piece of plastic. This process, also known as “cold fusion,” creates a joint that is chemically bonded and often stronger than the surrounding pipe.

While the fused joint itself is durable and resistant to chemical degradation, a number of factors can compromise its integrity, often leading to failure:

- Improper Installation: The most common cause of joint failure is incorrect application. This includes using the wrong type of cement, not applying enough cement, or failing to clean the pipes beforehand. If the two pieces aren’t joined immediately while the cement is still wet, a proper bond won’t form.

- Contamination: Any dirt, water, or other chemicals on the pipe surfaces can interfere with the chemical reaction and prevent a strong bond from forming.

- Expired Cement: The liquid solvent cement itself has a limited shelf life. If the can is old or has been left open, the solvents can evaporate, causing the cement to thicken and become ineffective. You should always check the manufacturing or expiration date on the can.

- Chemical Incompatibility: While the fused joint is highly resistant to many chemicals, it can be weakened by exposure to certain substances, such as some organic solvents, oils, and plasticizers, which can cause the joint to soften or crack.

According to the experts at the International Association of Certified Home Inspectors (InterNACHI), CPVC pipes are expected to last for 50 to 75 years under optimal conditions. Unfortunately, many area homeowners are seeing cracks in their CPVC installations after as little as 14 years. When those breaks occur behind walls or in crawl spaces, they can lead to an added set of risks for Houston families:

- Damage to drywall, flooring, and support structures

- Mold and mildew buildup in damp areas and the negative health effects caused by these fungal growths

- Increased risk of fire if water reaches the electrical wiring inside the walls

- Higher water bills

Scheduling a service visit from an established Houston residential plumber can provide added peace of mind for families worried about the risks of CPVC leaks and damage.

Other Materials Provide Greater Reliability

While CPVC is a popular and relatively inexpensive option for residential plumbing, two materials that are often considered superior for home water supply lines are PEX and copper.

PEX (cross-linked polyethylene) has gained popularity due to its flexibility, which allows it to be snaked through walls with fewer connections, thereby reducing the potential for leaks. PEX is also highly resistant to freezing and bursting, and its installation is faster and less labor-intensive than CPVC, as it doesn’t require solvent cement and a long curing period.

Additionally, PEX typically comes with an extended warranty that may last as long as 25 years. Some PEX manufacturers even allow homeowners to claim damages directly rather than going through the homeowner’s insurance policy. This alone can be a strong recommendation for PEX over CPVC pipe installations.

Copper, the long-standing industry standard, is known for its durability, resistance to corrosion, and ability to withstand high temperatures. Though more expensive and complex to install than both CPVC and PEX, copper is fire-resistant and has a proven track record of longevity, often lasting 50 years or more.

While copper pipes are typically regarded as the standard for excellence and longevity in the plumbing industry, they can also be expensive and experience issues in areas with high levels of acid in the water. If cost is not an issue, however, most professionals recommend copper pipe as the most reliable solution for residential plumbing needs.

By working with a company that handles all aspects of residential plumbing, homeowners can ensure that these technicians have the highest degree of expertise and knowledge regarding the best solutions for individual needs. Taking the time now to determine the type of pipes installed in your home and the health of your overall plumbing system can save you time and stress.

If you need help along the way, contact your Houston plumber.